- Completely made of GG30 cast iron by our own foundry

- Monoblock Cast Iron Body Design requires no heavy-duty fundament construction

- Fork Type Machining Head, 16000 rpm, 220 Nm torque

- Accuracy and usage norms are according to CE, VDI-DGQ 3441 and ISO standards

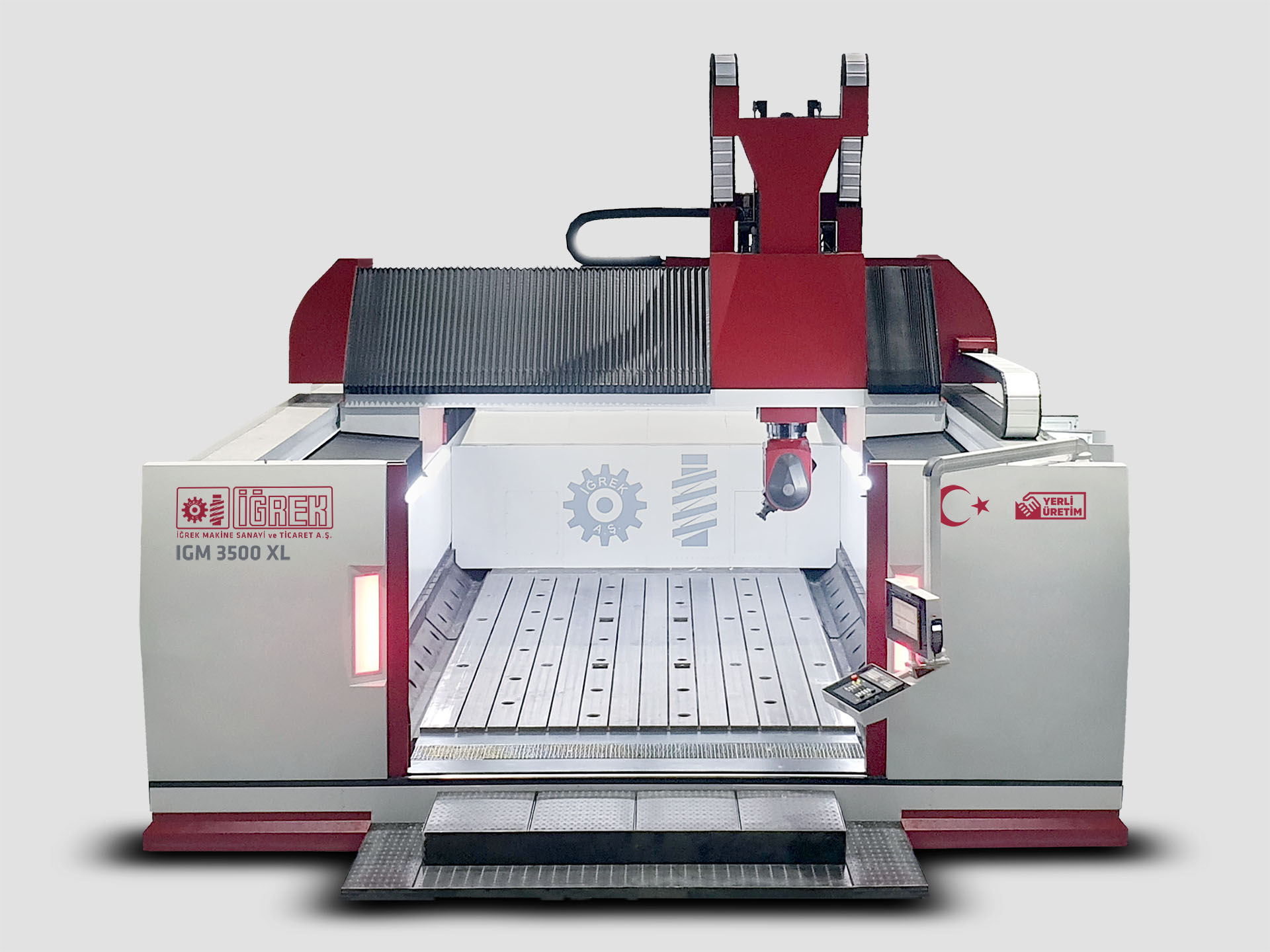

FR 3500

5-Axis Gantry Type Monoblock Milling Machine

Igrek Machine Tool IGM FR 3500 is completely made of GG30 cast iron by our own foundry. Stress relieving heat treatment was applied to the castings. The body parts are machined on precision milling machines and the linear guide mounting surfaces grinded.

All axes are water-cooled. This cooling system operates in the areas where the dynamic elements are located to minimize the distortion by thermal di erentiation that occurs during the movement of axes with heavy components. This special casting technique is under patent protection.

Components are measured and assembled using our Renishaw Laser Interferometer, precision Niveltronic devices with Bluetooth communication, Atos 3D Scanner and certi ed granite gauge blocks.

Axis drive systems are composed of high quality linear guideways, servo motors, gear units and rack and pinion gear systems. All axes are equipped with absolute measuring scales.

All kinematics, pneumatic, hydraulic, electrical and electronic components are selections of top-class products and brands for achieving the highest quality and reliability.

Our machine has high stability and accuracy thanks to its monoblock design. Our design is subjected to dynamic, static, stress, vibration and fatigue analysis by nite element methods and production was planned accordingly.

Inquiry Form

Send your inquiry and questions about IGM FR 3500!

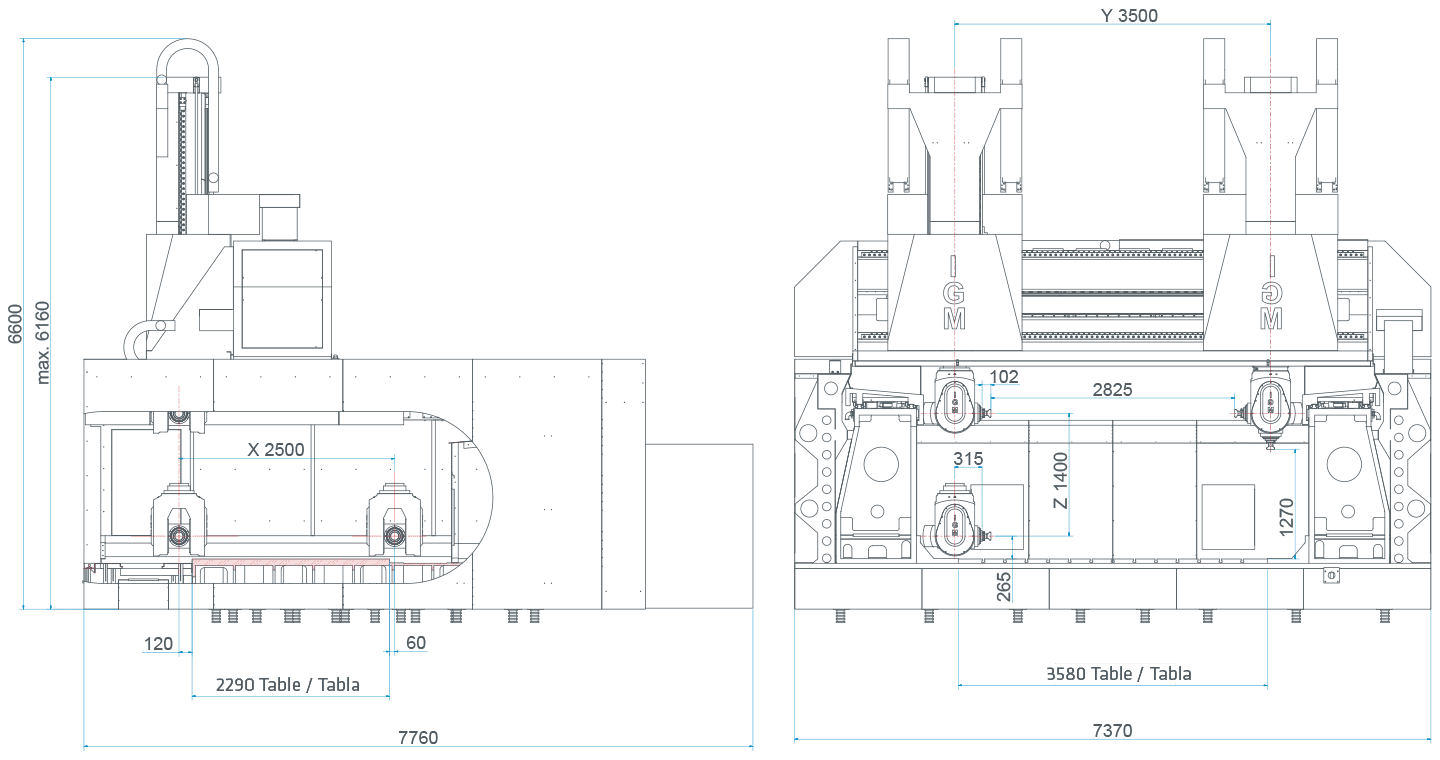

Technical Details

Igrek Machine Tool IGM FR 3500

Main body of the continuous fork type milling head is made of cast iron. The spindle is equipped with special ceramic bearings, pulverized lubrication system, internal and external cooling availability.

The spindle has a HSK-A 100 cone and it is also ready for ISO 50. The high-tech A-Axis and C-Axis are equipped with direct drive torque motors, brake systems and encoders.

| C-Axis Rotation | ° | ± 360 |

| C-Axis Power | kW | 22 |

| C-Axis Torque S1/S6 | Nm | 1200 - 1700 |

| C-Axis Speed | rpm | 50 - 120 |

| C-Axis Braking Torque | Nm | 4000 |

| A-Axis Rotation | ° | ± 115 |

| A-Axis Power (2 Motors) | kW | 6 x 2 = 12 |

| A-Axis Torque S1/S6 | Nm | 500 / 700 x 2 = 1000 / 1400 |

| A-Axis Speed | rpm | 50 - 120 |

| A-Axis Braking Torque | Nm | 4000 |

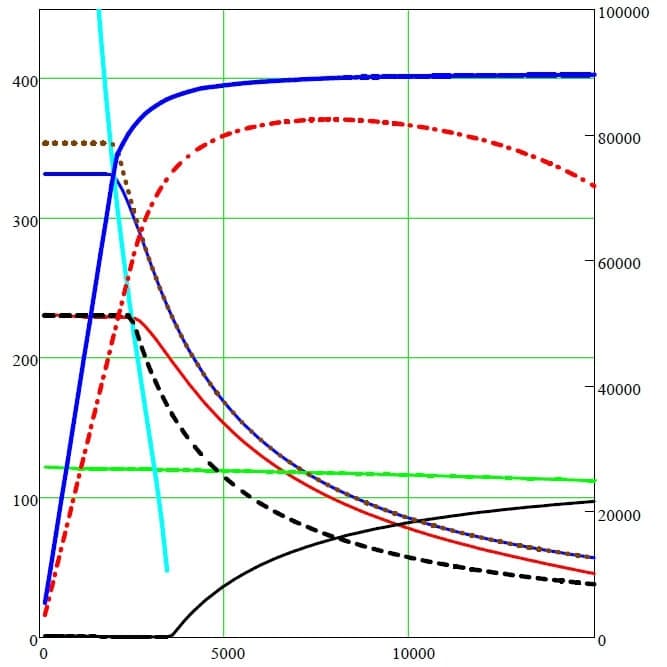

| Spindle Power | kW | 60 |

| Spindle Torque S1/S6 | Nm | 210 - 310 |

| Spindle Speed | rpm | 16000 |

| Tool Taper | HSK-A 100 |

- S1 torque

- S6 torque, 5%

- Maximum current

All equipment used in our machines are selected from the top series of the leading brands of their class and high quality sustainability is targeted with strong communication and mutual support with our suppliers.

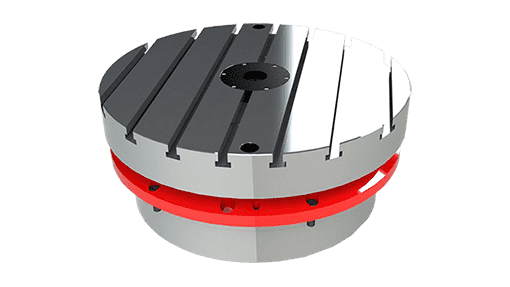

Rotary Table

According to customer demand, we can provide 700 mm diameter, 300 rpm rotary table with vertical turning feature. Our target in near future is to supply much larger, powerful rotary tables, which are our own production.

Automatic Tool Changer

With 24, 48 or 96 tool changing capacity on request

Electrical Panel, Automatic Lubrication, Cooling, Hydraulic & Pneumatic Systems

Chip Conveyor

Photos

- All

- FR 3500

- Milling Head

- Operator Panel

E-Catalog

For more information about Igrek Machine Tool IGM FR 3500, please download the e-catalog!

Inquiry Form

You may send your inquiry and questions about Igrek Machine Tool IGM FR 3500 by filling out the form below.